How Artificial Intelligence Is Creating Better Design Solutions

“Generative design is a purposeful approach to design that brings ease to you and helps you create faster, more informed design decisions.”

Anonymous

Imagine a magical land that can auto-generate ‘stuff’ that would make life easy by just stating what you want. All you need is to inform it of what you want and leave it to cast different options of results for you. For instance, you might decide to create a perfect Veterinary that would not only take into account movement of man but also animals.

The traditional method would be to sit down and manually conceptualize how you want your design to look like or at best look at other designs and seek modification to suit your budget.

You would then have to manually calculate your design parameters, taking into consideration movement and ergonomics for animals and man, the impact on building loads, and construction costs.

Don’t Miss Out: Join our Facebook Group for funny and motivational quotes @ livegamefully

However, what if you can tap into the booming technology of artificial intelligence that’ll proffer numerous design solutions by just stating your required parameters?

Generative design is a creation tool in which a designer simply states design parameters (the goals and constraints of the project) and leaves artificial intelligence algorithms to generate and evaluate hundreds of potential design solutions for a product idea.

READ MORE: HOW TO PROMOTE AND INCREASE ENROLLMENT FOR YOUR ONLINE COURSE

Generative design draws on cloud computing and extensive use of artificial intelligence to create parts and products (could be images, sounds, architectural models, animation, and much more), unlike anything engineers, might come up with on their own.

The emergence of Artificial Intelligence has made seeming complex design solutions simpler and has found profound usage in virtually every field which does not exempt additive technology and 3D printing.

All you have to do is to input quality data as the Artificial Intelligence-based design tool operates on the popular GIGO (“garbage in, garbage out”) concept, in which a flub in input data will produce flubbed results.

How does Generative Design relate to existing technologies?

Generative design uses Artificial Intelligence based algorithms to provide the best design solutions possible to a given parameter.

Other technologies that perform similar functions as generative design such as topology optimization, lattice optimization, parametric or similar technologies, are entirely focused on upgrading and improvement of existing designs not creating a new concept.

Similarly, generative design provides more than one design solution. These solutions are invariably pruned to the best of the best by the designer.

READ MORE: THE KAIZEN RECIPE FOR SELF AND BUSINESS IMPROVEMENT

In addition, generative design yields many high-performing, cost-effective design solutions instead of one upgraded version of a known solution.

Evolution

“Architects have been using scripting for decades to take the geometry created by a computer and manipulate it in new ways, and a new generation of building design and construction was born. Computers overruled the tyranny of the right angle, and shapes and curves became possible not to just draw but to build.”

Phil Bernstein, Associate Dean and a Senior Lecturer at the Yale School of Architecture describes the history behind scripts, algorithms, and generative design.

Traditionally, design requires that you use basic techniques like sketching to manifest the ideas in your mind. You can use CAD software like AutoCAD, etc.

Parametric and automation design quickly took over. In parametric design, all you have to do is define relationships between traditionally drawn or sculpted elements. While design automation, for instance, helps you create tasks within a parametric design.

Enter generative design, this provides out-of-the-box creative solutions by providing variations of possible design solutions with data input to it. Its origins are not clearly documented, but it has been used since the 1970s as a way to approach complex design situations.

With the use of Artificial Intelligence, generative design eliminates trial-and-error processes that you have to go through to achieve optimal structures.

Generative Design and Additive Manufacturing

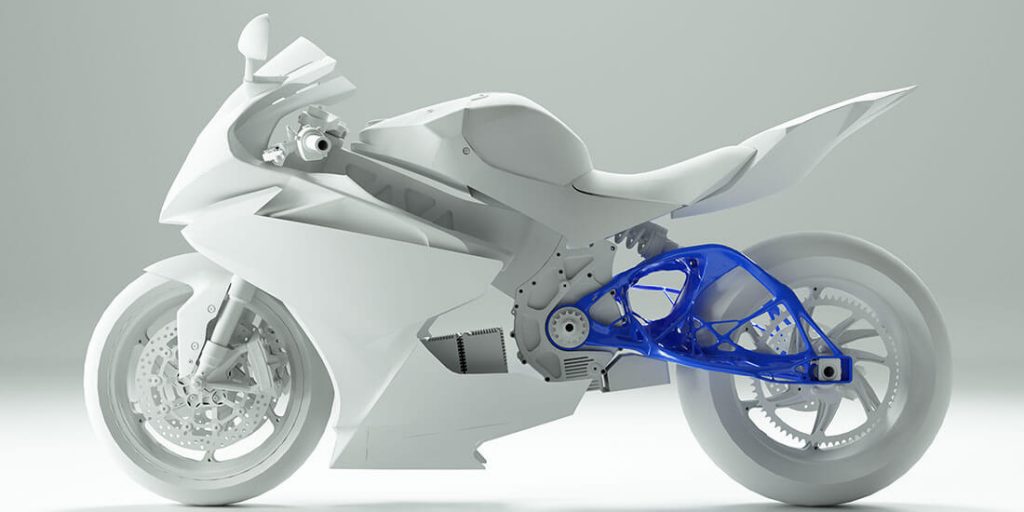

Generative design’s utmost goal is not in conceptualizing or creating a plethora of designs rather the ability to print the designs in three dimensions.

At the end of a generative design analysis, designers and engineers are presented with several ready-to-manufacture design solutions. The advent of 3D printing technology makes the design solutions easier to create.

Additive manufacturing is the production of a three-dimensional object from a CAD model. It builds 3D objects by adding layer-upon-layer of material. It makes use of a variety of materials like biochemicals, ceramics, metals, and thermoplastics.

Read More: HOW TO CREATE YOUR SUPERBETTER 2021 PLAN

3D printing and additive manufacturing has been used interchangeably in modern days, 3D printing is the ability to produce very complex shapes or geometries that would be otherwise impossible to construct by hand, including hollow parts or parts with internal truss structures to reduce weight while Additive Manufacturing (AM) gained popularity in the 2000s inspired by the theme of material being added together (in any of various ways).

With the popularity of 3D printing, generative designs can now be produced with minimum fuss with accurate parameters as provided during the design stage.

Benefits and Real-World Applications

You have to think of generative design software as an assistant that helps with creating, testing, and evaluating options. The collaboration between humans and Artificial Intelligence to birth generative design has a plethora of benefits, some of which are highlighted.

The benefits generative design has brought to Engineering, art, and design is colossal and there is a potential paradigm shift in the design industry. Let’s take a deeper look at some of the reasons hardware engineers and product designers should key into this technology

- Liberation from the tedious trial and error: Let’s be factual, it’s daunting and boring to keep reviewing and upgrading the same product over time that would consume unnecessary time trying to get a perfect product.

Generative design provides an almost perfect product when almost perfect parameters are inputted

- Self-improving feedback loop: With the fusion of generative design with other technologies, generative design is able to simulate the entire lifecycle of a product and extend its peak performance. This simulation helps provide a feedback loop that can be used to optimize designs.

- Reduced cost: Cost is eventually reduced when design solutions are created with minimal trial and error process. Limited usage of materials and reduced down-time would eventually save money.

- Many options to select from: A successful generative design will create a multitude of design solutions. You only need to step in again and choose one or a few solutions based on your own criteria and experience.

- Wholesome printable Assembly: The advent of additive manufacturing (like 3D printing) processes is of immense benefit to the designer. This technology will not only assist you in having a 3D design but also a whole assembly at a go that can also be used to replace many fused parts.

- Ideal for rapid prototyping: The digital process means that design alterations can be done quickly and efficiently during the manufacturing process.

How generative design has been applied in Industries

Engineers and Designers are already starting to leverage generative design software to create new design solutions. Popular amongst the many examples of the application of generative design are:

The British Museum’s Great Court: The Museums court is a great artery and has since restored to form a new civic space. The Director of the Design Museum, Deyan Sudjic, said “With its mix of architecture and urban design, and its confrontation of classicism with computer-generated design, the British Museum’s Great Court is one of the defining buildings of Norman Foster’s career.

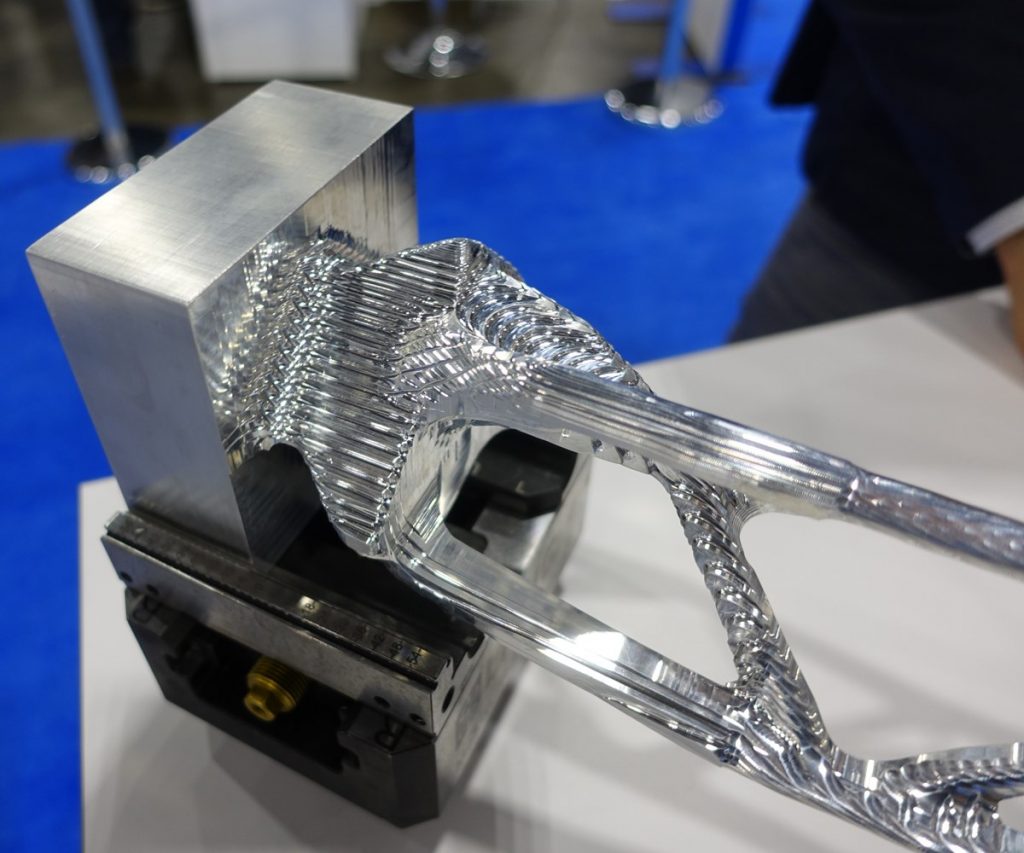

Jet Engine Bracket: In 2013, GE and GrabCAD launched the 3D Printing Design Quest where they challenged the public to redesign a metal jet engine bracket with some given parameters. M Arie Kurniawan, an engineer from Salatiga in Central Java, Indonesia, came in first place in the global 3D printing challenge

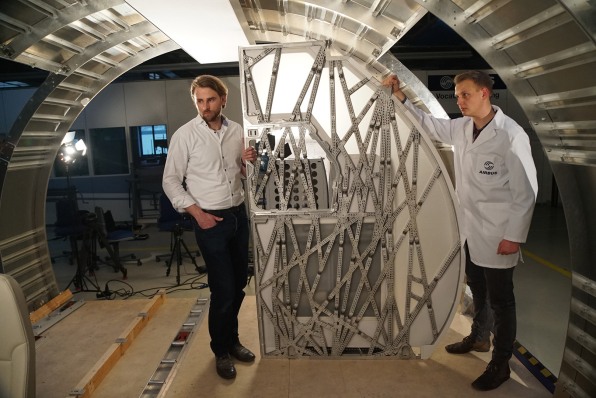

Airbus A320 Cabin Partition: Airplane manufacturer Airbus also used a generative design to reimagine an interior partition for its A320 aircraft and came up with an intricate design that ultimately shaved off 45 percent (30kg) of the weight off the part.

MaRS Innovation District: MaRS Innovation District of Toronto used generative design to create the floor plan for an office environment that would not have been possible to create by humans alone. The idea was to optimize the office environment using certain criteria that included leveraging natural lighting and minimizing employees’ visual and sound distractions.

Going forward

According to research published by Autodesk, nearly half of design firms are aware of generative design tools and over a third are currently implementing them

I mentioned that Greenhorn engineers can quickly start producing successful generative models with minimum fuss that would have ordinarily taken donkey years to master and start designing. For engineers of any level, generative design should shift their role to curating parameters and test conditions,

Although generative design tools are a probable game-changing technology, they simply can’t replace skilled designers, architects, and engineers. What makes this technology so powerful is the collaboration between humans and machines.